Tech Corner: What Is Tape?

What is tape? A simple question deserves a simple answer, one anyone could seemingly provide. After all, we all know what tape is, right?

Or do we?

Try explaining it aloud, as if describing it to a person from another planet where tape doesn’t exist. Not so easy. Sometimes, the simplest things are the most difficult to put into words. And as we’ll learn today, sometimes things we thought were rather simple, like tape, end up being quite complex.

What is tape?

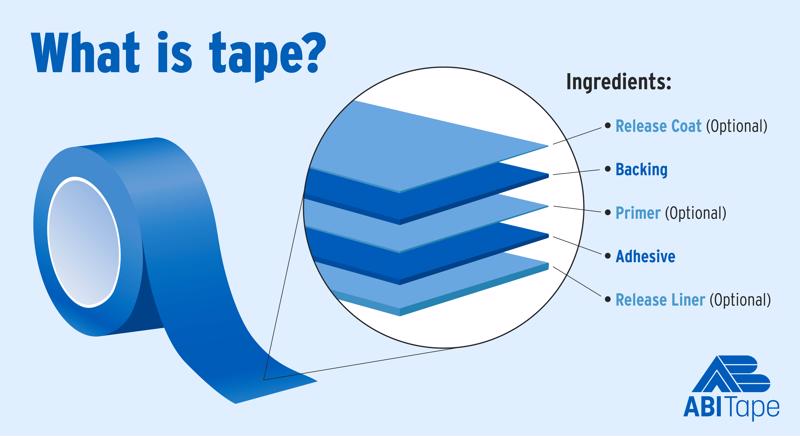

Tape is a flexible material wound into a roll and contains two major components: a flexible backing and a special class of adhesive called a pressure sensitive adhesive (PSA). This adhesive can be placed on one or both sides of the flexible backing. Tape sticks when applied to compatible surfaces, creating a surface bond that holds objects in place (hold-down tape), prevents exposure (protective tape) or affixes ancillary components to a substrate (transfer tape).

That much you may already be familiar with, but each tape product is comprised of separate ingredients that come together to make tape. Learning a little about what components go into tape products may provide you with valuable insight into how truly technical tape can be, especially single-coated tapes.

Backing

Nearly all single-coated tape products require a foundational layer, a backbone which the rest of the product relies on for support. Tape backing can be made from paper, plastic, cloth or metal. Which one you use depends on the how you plan to apply it, what you plan to apply it to and under what conditions the tape will ultimately be subjected.

Tape backings can also undergo surface treatment to preempt common application issues notorious to any person who has ever taped anything. Optional release coats, for instance, stop a strip of tape from sticking to itself without jeopardizing how it sticks to the intended surface. Release coats also make tape easier to unwind from its roll for a faster overall application.

Many tapes also receive a layer of primer between the backing and the adhesive to enhance anchorage. Primers ensure a strong bond and prevents adhesives from leaving a residue.

Adhesive

Tape adhesives consist of polymers designed to activate once the user applies pressure. Depending on the intended application, adhesives can be permanent or removable. They can be made from rubbers, resins, acrylic, silicone, or a polymer blend. Adhesives are also typically treated with additive chemicals that allow them to withstand adverse conditions like extreme temperatures or oxidization over time, which compromise their tack.

“Release agents prevent the release liner from sticking to the adhesive layer.”

Release liner

Although we said almost all tapes contain backing earlier, some don’t. This class of tape is typically referred to as “unsupported.” Transfer tapes, for instance, only consist of an adhesive layer and a release liner.

Release liners may look similar to standard backing at first glance, but release agents differentiate the two. These agents, usually made from silicone, prevent the release liner from sticking to the adhesive layer. Single-coated tapes may include a release liner as opposed to a release coat, depending on end use. Additionally, double-sided tapes may contain both a backing and a release liner, along with two layers of adhesives.

Pressure

No tape will stick without pressure, and the amount of pressure applied can determine how well tape sticks in most cases. That said, adhesive freshness matters just as much – for adhesive polymers to function properly, they must both adhere to the backing or release liner as one cohesive substance, as well as transfer freely to the substrate being taped over. The texture of a given substrate aids in this process, but pressure sensitivity is the catalyst that sets everything in motion – or sticks it in place, as the case may be.

As you can see, tape represents a confluence of many different mechanical and scientific forces working together to create a desired effect. While we may have a roll sitting around every arts and crafts cubby or junk drawer in our houses, industrial tape used in manufacturing and other such industries requires a working knowledge of chemical properties to be utilized effectively.

Long story short: Never underestimate what tape is capable of. Not only is tape a fascinating scientific marvel, but its endless customization potential means we’ll be talking about its greatness for a long, long time. Stay tuned for the next installment of Tech Corner where we’ll discuss the intricacies of Pressure Sensitive Adhesive.